Features

Product Overview

GDI Engine Control Unit

MAIN FEATURES

• 20 single-ended inputs

• 8 frequency inputs, 4 VRS/Hall - 4 Hall/Rate

• 4 inductive or logic command ignition drivers

• 4 Peak&Hold injector drivers for GDI

• 2 Half-Bridge: DC-Motor driver for “Drive by Wire” control

• 2 PWM (Current controlled PWM)

• 2 lambda UEGO sensors with heater

• 1 knock input for detonation

• 3 CAN lines 2.0B

• 1 Ethernet line (100 Mbit/s) and 1 USB 2.0 line

• Up to 1 GByte internal storage for data logger

DESCRIPTION

Designed as the latest evolution in the series of SRG control units, the SRG-340 EVO introduces multi-core functionality for an increased computational power. The unit can drive up to 4 Peak & Hold GDI injectors, a High Pressure Pump with 8 A peak current and 5 A hold current and up to 4 ignition coils, including logic command coils (SW option). The Actuation core, based on a high performance PowerPC microcontroller and an FPGA for diagnostic purposes, manages injection, ignition and general power

output. The data logger and communication processor is an ARM 32 bit Cortex with a flash disk up to 1 GByte. The communication with other units, such as dashboards and loggers or from the PC-based configuration tool, made through 3 CAN lines, a 100 Mbit/s Ethernet line and a full-speed USB 2.0. The unit provides analogue inputs for single-ended, temperature and knock-sensors and an interface for a switching lambda sensor. The unit also provides Half-Bridge output stages for use with suitable “Drive by Wire” actuators. Up to 10 configurable speed sensor inputs (Inductive, Rate or Hall), provide full flexibility of configuration for engine-angle detection and other frequency inputs, such as wheel or shaft speed.

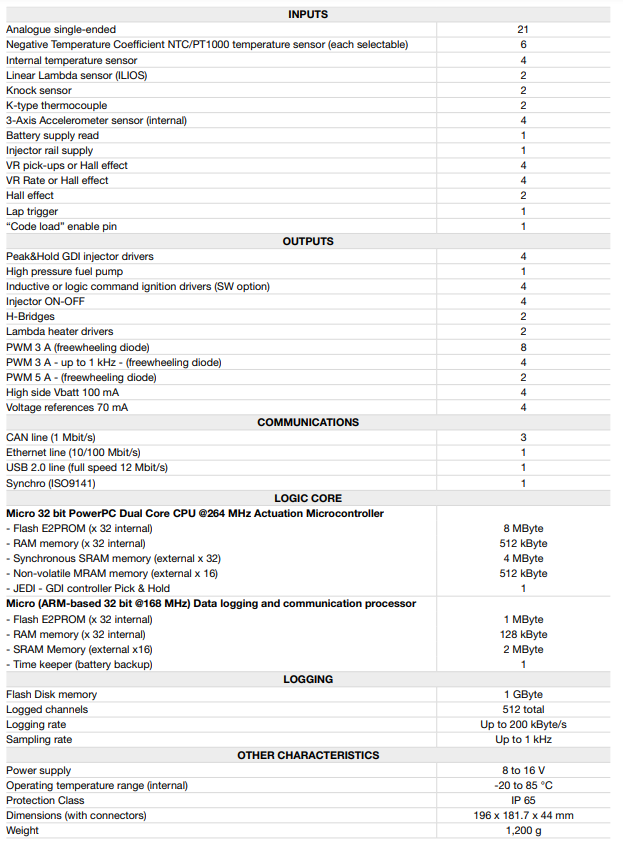

TECHNICAL CHARACTERISTICS