Features

Product Overview

Measurement, Calibration and Setup PC Software

DESCRIPTION

SYSMA is the new Marelli integrated PC Software designed for the configuration and tuning of vehicle control systems for the most advanced levels of motorsport.

SYSMA is the integration and evolution of previous Marelli PC tools for ECU monitoring and calibration, Data Logger, Dashboard setup and Codeload management.

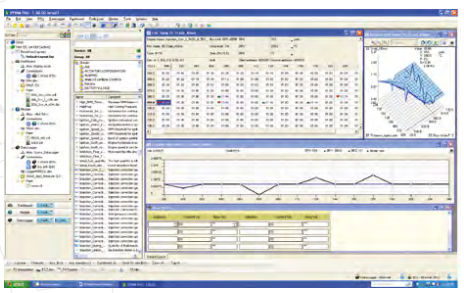

SYSMA include a range of environments for data analysis and data management. A complete suite of graphical instruments allows you to monitor and tune the entire system. A large set of user customisable keyboard accelerators make SYSMA easy and quick to use.

SYSMA handles all configuration files, analyses the data measured and reprograms the HW devices while also flashing the embedded firmware.

SYSMA allows full configurability of the screen layout in accordance with end-user preferences (layouts, windows, parameters, hot-keys).

SYSMA allows the comparison and merging of data versions, importing data between different firmware releases.

SYSMA is a flexible software designed to be compatible with universal standard automotive platforms (ASAM), in order to ease the exchange of data between electronic and software suppliers. At the same time, SYSMA implements data formats and protocols dedicated to the Motorsport world and its requirements regarding performance and reliability.

SYSMA supports open architecture in order to allow integration with additional custom software tools. Public services are provided in order for other applications to fully control the system via SYSMA functions. SYSMA is compatible with all the latest Microsoft Operating Systems Windows® 7, Windows® 8 and Windows® 10.

This is the result of more than 25 years of continuous evolution and close partnership with the top-ranking teams in F1, FIA, FOM, WRC, Le Mans, GT, MotoGP, SuperBike, AMA, and Powerboats.

MAIN FEATURES

• SYSMA is compatible with all the latest Microsoft Operating systems such as Windows® 7 32/64 bit, Windows® 8 32/64 bit and Windows® 10 32/64 bit.

• Advanced interactive Graphic User Interface

• Project management

• Data Logger Setup

• ECU Calibration and Setup

• Dashboard Editor

• Integrated programming tool for flashing firmware

• Simultaneous monitoring and recording of measurements from ECU and Data Logger

• Save measurements in WinTAX4 data format

• Integrated Math Channel Editor

• System database management for calibration and measurement

• User Level Access management

• Compare and merge data versions, importing data between different firmware releases.

• Supports Ethernet, CAN and Bluetooth lines

• Compatibility with standard commonly-used CAN Cards (Vector, Peak, CanDo)

• External potentiometer management (Desk AMC6 / AMC4)

• Compatibility with ASAM standards: MCD-3 (test bench interface), MCD-2 MC (ECU description for

measurement and calibration system)

• Supports standard DBC Vector database formats (Communication Database for CAN)

• Supports Standard CAN signals (advanced graphic editor for CAN messages)

• Complete Customisation: layouts, graphs, math libraries and colour schemes to suit user preferences

• Open to standard tools: e.g. Excel®, Matlab® and Simulink®

• OLE/Automation inter-process communication protocol supported

• Interfaced to third party data systems via dedicated APIs

• Extensive contextual HELP

• Compatibility with all Marelli Motorsport products

Project Management

All the system files (ECU calibration database, Data Logger Tables, firmware, settings…) are included in “project” files. This results in simplicity and reliability of management for data

versions. SYSMA easily allows the updating of the calibration and measurement database to newer embedded software versions. Furthermore, SYSMA provides all the functions necessary in

order to configure, modify, setup, export and import parameters and calibration to and from projects. SYSMA allows you to convert old Marelli setup files (Axon (TPX), Vision (PTA), Sysfiles (CLL), Exefiles (CDL, Bin)) to new projects. Data Logger Setup and Monitoring SYSMA integrates all functions of logging setup. In a very simple manner it allows you to connect to the Data Logger and to generate the measurement logging table.

The main SYSMA Data Logger features are:

- Real time display of logged measurements

- Setup of signals to be acquired

- Setup of all Data Logger options (e.g. Trigger options)

- Management of multiple sets for logging tables

- Management of protected subsets of measurements for different Users

- Comparison and merging of logging tables

ECU Measurement and Calibration Management

SYSMA integrates all functionalities for ECU Measurement and Calibration management.

The main SYSMA Measurement and Calibration features are:

- Real time display of measurements

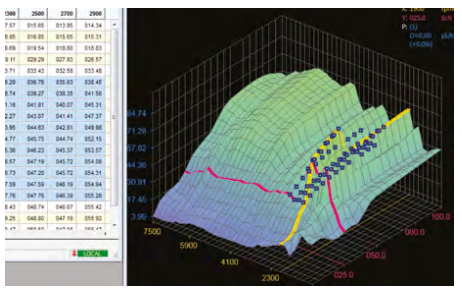

- Editing parameters, including 2D and 3D maps

- Parameter subsets for single applications (e.g Chassis, Engine,...)

- Management of multiple sets for calibration values (e.g. set for “Dyno”, set for “Race”, set for “Raining Race” etc. within the same project.

- Integrated calibration manager tool for the comparison and merging of calibration parameters

- Supports Ethernet and CAN protocols

- Supports Bluetooth protocol

- SYSMA allows the control of multiple ECUs

- One ECU can also support several SYSMA clients.

- ASAP3 protocol support for automated tuning

- Recording of ECU parameters in Wintax4 format

- External potentiometer management (desk AMC6 / AMC4)

Dashboard Editor

SYSMA integrates all functions for Dashboard Setup.

The main features are:

- Graphic Dashboard setup

- Bitmap libraries

- Font libraries

- Dashboard Layouts

- Alarm configuration

- Multi-page support

Firmware Codeload

SYSMA integrates all functionalities for programming all system devices: ECU, Data Logger, Dashboard and Modules. The main features are:

- Integrated Codeload programming environment

- Automatic project update with new firmware

- Simple monitoring interface for standard Users (progress bar and basic status messages)

- Advanced debug instruments for expert Users, advanced codeload options SYSMA protocols support commands to switch the device to codeload mode via software without the need to access the wiring.

Monitoring and Recording

SYSMA provides a large quantity of functions which allow

for the visualization and recording of measurements from the

system devices:

- Instrument and Gauge controls

- Alphanumeric data & Statistics

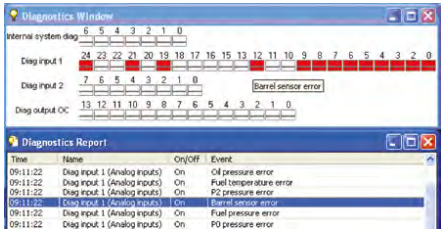

- Diagnostics and Alarm

- Oscilloscope

Instruments

The overall appearance of the instruments is fully configurable to suit your preferences or to adjust the display to different brightness scenarios (garage, outdoor etc.)

A large range of styles allows you to customize the appearance of the instruments and to adapt them to SYSMA layouts.

All parts of the instruments can be configured: scale, font, colours, dial hands, alarm, layout, tick marks and units.

The instruments provide a real time display of the variations in parameters.

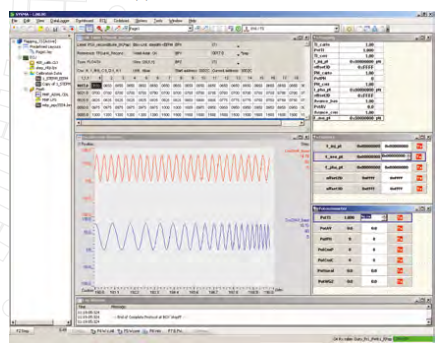

Oscilloscope

Shows measurements as waveforms against time

- Real time analysis

- Multi channel graphs

- Analysis cursor

- Measurement listing and values

- Save data in Wintax4 format

- Math Channel support

Displaying Measurements

The Measurements display mode presents each channel as a label followed by its real time value, measurement unit and an optional graphical representation. Values are re-read with each refresh cycle.

Potentiometer Measurements

Potentiometer mode allows the user to enter a replacement value for a specific channel which is then transmitted to the electronic device.

Potentiometer Measurements

Potentiometer mode allows the user to enter a replacement value for a specific channel which is then transmitted to the electronic device.

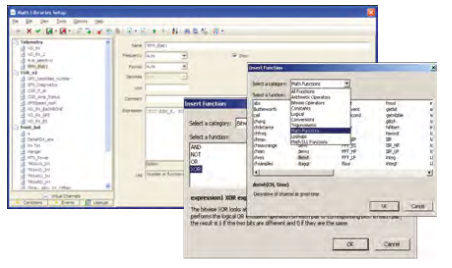

Maths channels

Virtual channels are generated via user-defined measurement functions. A graphical editor with advanced features allows complex math expressions to be quickly built up.

Virtual channels can also be organised into libraries.

Calibration Tuning

SYSMA provides a large range of functions which allow for

calibration editing and managing for all system devices. The

main features are:

Calibration Editor

The Calibration Editor is the core display for tuning vehicle

calibration maps.

- Change values by typing into cells

- 2D and 3D maps can be viewed as graphs. Change values by

dragging points on the graph.

- Export/Import calibration values to/from Excel, CSV

- String enum value support

- Mapping/Work Point function to write potentiometer

corrections to ECU

- Extract calibration data from the ECU and also perform

comparisons with other sets of data.

Read/Write

This special display allows administrators to read/write any software variable allocated in the unprotected areas of ECU memory.

Desk Potentiometer support

SYSMA supports external potentiometers (Desk AMC6/AMC4) where it is possible to modify operating parameter values in a faster manner via rotary dials instead of using the PC keyboard.

Mapping Function

The SYSMA Mapping function allows you to write correction values for the maps contained in the ECU directly. It includes the possibility to open multiple maps at the same time (e.g. advance, injection, etc.) while managing corrections. Asap3 protocol support SYSMA supports Asap3 protocol and allows communication with commonly-used dynamometric benches (e.g. PUMA-AVL).

Multi-Device support

SYSMA supports multi-device programming for automatic device setup. Both ECU and Logging operations can be activated automatically as soon as the selected devices are

available.

Software Coherency

SYSMA supports advanced coherency mechanisms allowing the automatic checking of coherency between firmware addresses and project addresses in order to avoid accidental

memory writing.

Remote Update package

SYSMA supports device update via encrypted auto-launch project packages for the remote updating of customer devices.

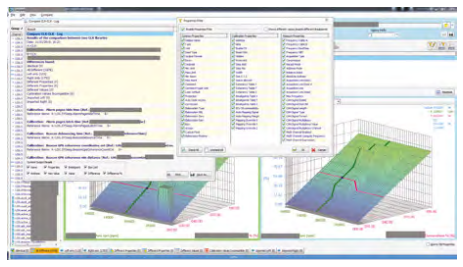

Compare & Merge

Compare

SYSMA implements an enhanced integrated comparison tool. It allows the comparison of calibration & measurement sets as well as the logging tables. All the results are clearly displayed in a report where you can also copy values from compared sets.

- Textual display of differences

- 2D and 3D graphic display of differences

- Parameter comparison selection

- Left/right only comparison

- Direct data editing

- Use Right/Use Left value & properties

- Single Map comparison support

- Support for calibrations not part of the project

Merge

The merge utility is dedicated to the updating calibrations values to the newer software embedded projects.

It allows the simple copying of all vehicle setups between different software versions. SYSMA in fact automatically copies all parameters’ values into new firmware addresses without the need for user interaction. On completion of merging, a detailed report is produced for easy reference.

Standard Formats and Interfaces

- Supports ASAM standards MCD-2 MC (ASAP2 - ECU description for measurement and calibration systems): import A2L and MOT allows the creation of a parameter database based on standard automotive files

- Supports ASAM standards MCD-3 (test bench interface): ASAP3 protocol support for automated tuning

- Supports an extensive range of hex file formats such Motorola S or INTEL-Hex

- Supports CAN db for CAN monitoring and sending

- Supporsts standard DBC database format (Communication Database for CAN)

- API for interaction with Windows® PC applications

OLE Automaton

SYSMA provides powerful possibilities for interfacing with external applications using Automation Server technology (formerly OLE Automation Server). Automation is a protocol which allows an application to make its own objects available for use in other applications, programming tools or via scripting languages.

In this way SYSMA can be run and controlled by any program which has the characteristics of an Automation controller. Applications which make excellent use of Automation include Microsoft Excel®, Access®, Project®, Matlab®, Simulink® and many others written in Visual Basic or Visual C++.

It is possible, for example, to open a SYSMA window from an Excel spreadsheet, analyse information via Matlab, or run commands directly from an external application written in

Visual Basic.

SYSMA APIs

A complete suite of add-on modules increases the potential of SYSMA, allowing – together with API interfaces - use in conjunction with external applications.

The API layer allows 3rd party applications to read and write measurements and calibrations.

Main API functionalities regard:

• Data Logger parameters

• ECU parameters

• ECU Calibration

• Codeload

Complete Customisation

The main screen area of SYSMA contains graphic or alphanumeric analysis windows in which logged data may be represented in a variety of ways. Each User may save commonly-used combinations of analysis windows as Layouts, allowing the waveforms to be organised into logical screen containers.

User-configurable accelerator keys make SYSMA easy to use. Colour schemes allow the overall appearance of SYSMA to be changed to suit User preferences or ambient light conditions

(e.g. Pitwall, Garage etc.). Global settings can be modified locally to each window rendering SYSMA fully adaptable to all requirements. For each window, colours, styles, fonts, scales, filters, channel position etc. can be changed.

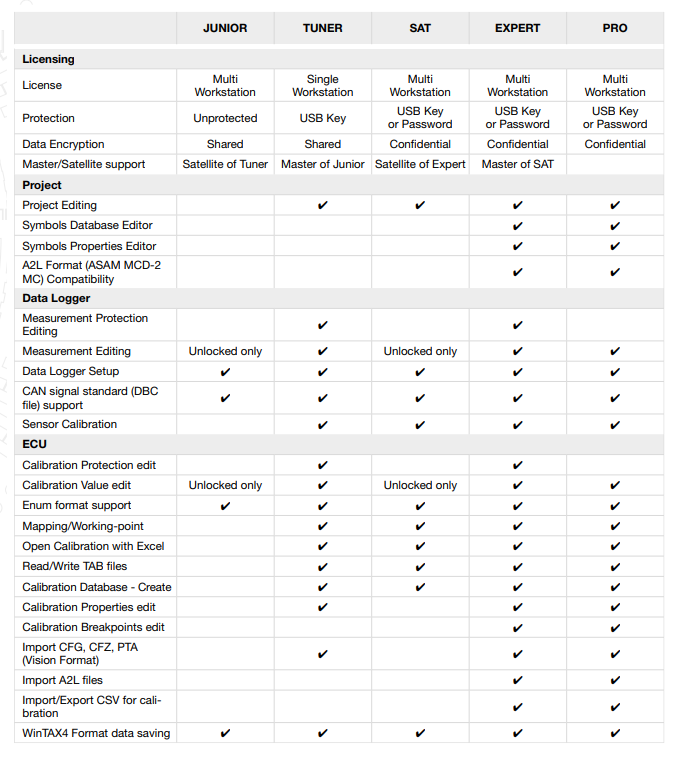

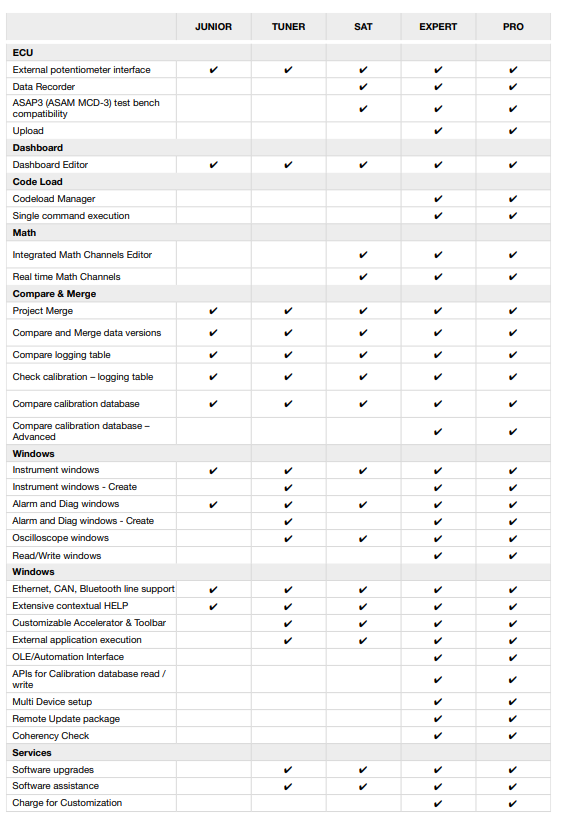

SYSMA License Features

SYSMA is licensed with five different levels: PRO, EXPERT, SAT, TUNER, JUNIOR

- TUNER & JUNIOR are simple SYSMA versions with JUNIOR support being the satellite of a TUNER version

- EXPERT & SAT are complete SYSMA versions with SAT support being the satellite of an EXPERT version

- PRO is the complete version without the need for the Master-Satellite setup